Development of Environmental Technology for Steelmaking Process

Project overview

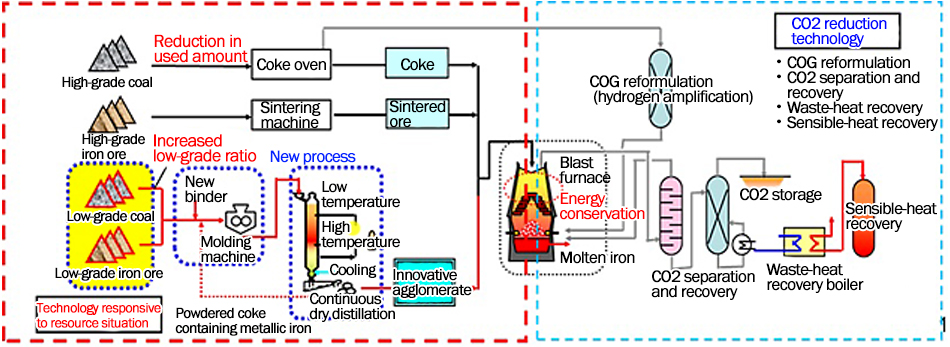

The steel industry emits more CO2 than any other industry in Japan's industrial sector. In particular, manufacturing steel using the blast-furnace method results in high emissions, so drastic reductions in CO2 emissions are needed as a global warming countermeasure. In global terms, Japan's steel manufacturing technology is already state-of-the-art, and Japan already conserves as much energy as possible by utilizing waste heat and by-product gases. Therefore, to achieve reduced CO2 emissions on a global scale, it is necessary to develop innovative steel manufacturing technologies.

-

Development of Environmental Technology for the Steelmaking Process

Development of Environmental Technology for the Steelmaking Process

Research and development item 1. Development of hydrogen reduction and other technologies (phase II - step 1) (starting in FY2018)

This item involves the development of technologies for reducing iron ore by amplifying the hydrogen included in the high-temperature coke oven gas (COG) generated during coking and using it as a partial substitute for coke. This item also involves the development of innovative CO2 separation and recovery technologies that utilize the unused waste heat of steel mills to separate CO2 from blast furnace gas (BFG).

During phase II - step 1, a 12-m3 scale test blast furnace and an actual blast furnace will be used for partial verification, and then a numerical analysis model will be utilized to perform scaled-up verification of a hydrogen reduction-utilizing blast furnace. In addition, to reduce the costs of CO2 separation and recovery and utilize unused waste heat, verification of its practical application will be performed. Technology that makes it possible to ultimately reduce the CO2 emissions of steel mills by approximately 30% compared to the current level will also be developed.

-

Test blast furnace (Kimitsu Steel Works)

Test blast furnace (Kimitsu Steel Works)

Research and development item 2. Development of ferrocoke-utilization process technologies (starting in FY2017)

This item involves developing and demonstrating energy-conservation technology that makes it possible to reduce the amount of coke put into a blast furnace by utilizing the catalytic effects of metallic iron included in ferrocoke—which is generated as a result of the mixed hybrid molding and dry distillation of thermal coal and low-grade iron ore during the pig-iron manufacturing process that makes up part of the steel manufacturing process—to dramatically increase the blast furnace reduction efficiency.

-

Ferrocoke

Ferrocoke

Basic information

| Technical field |

|

Project code | P13012 |

|---|---|---|---|

| Department in charge |

|

||

Last Updated : April 13, 2022