Basic Technology Development Project for Metal Additive Manufacturing Parts

Project overview

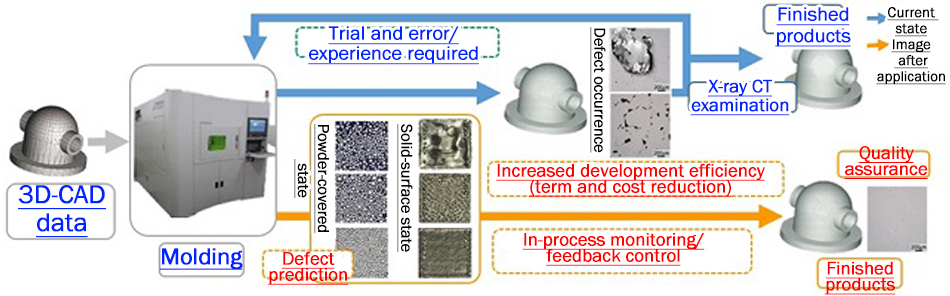

Metal additive manufacturing technology is expected to be applied to parts processing in fields such as aerospace, industrial equipment, and medicine. However, in the fabrication of high-value complex shapes and high-performance components, ensuring quality reproducibility and the time and cost required for development are issues.

This project aims to elucidate the melting and solidification phenomena of metals in metal additive manufacturing, and develop advanced measurement and mechanical control techniques in the process to ensure high quality and efficiency in the development of metal additive manufactured parts and other products.

Research and Development

In metal additive manufacturing using the powder bed method (laser beam and electron beam), NEDO is working on the following developments.

[1] Development of Technology to Predict Defect Occurrence by Elucidating Melting and Solidification Phenomena

Observes and measures the metal vapor and metal droplets (spatter) that causes of defects, temperature distribution, and the properties of the molded surface, in order to elucidate the defect generation mechanism. Also develops defect occurrence prediction technology by analyzing the relationship between defect occurrence causes and molding conditions using machine learning and simulation.

[2] Development of Advanced Monitoring and Feedback Control Functions

Develops advanced monitoring and feedback control functions to detect defects that occur during the molding process in real-time with high accuracy and repair defects by remelting.

[3] Implementation of Development and Evaluation Methods for the Fabrication of Additive Manufacturing Parts

Uses predictive technology for defect generation and advanced monitoring and feedback control functions to prototype and evaluate molding samples and accumulate data. Then, based on the data accumulated under various molding conditions and materials, methods and systems will be developed to enable users to efficiently develop and evaluate additively manufactured parts.

-

Overview diagram showing the image flow before and after the application of research results

Overview diagram showing the image flow before and after the application of research results

Basic information

| Technical field |

|

|---|---|

| Project code | P19007 |

| Department in charge |

|

Last Updated : January 24, 2024