Development of New Innovative Composite Materials and Forming Technologies

Project overview

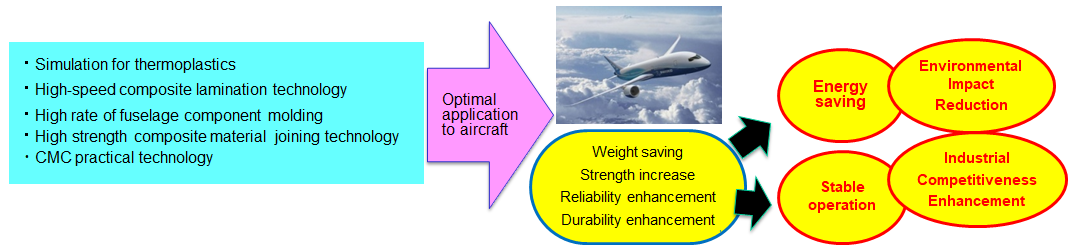

In the aircraft industry, there is a market need to reduce energy consumption and CO2 emissions by improving aircraft fuel efficiency, maintainability, and safety, and highly advanced technology development of composite materials as structural members for weight reduction is underway. As international industrial competition intensifies, there is an urgent need to develop these components and processing technology.

In this project, NEDO aims to resolve the above issues and strengthen the international competitiveness of the Japanese industry by developing aircraft structural components and processing technology, as well as lightweight, heat-resistant CMC*1 engine components.

-

Project explanation diagram

Project explanation diagram

Research and Development

Development of Airframe Design Technology to Realize Ideal Airframe Structure in the Composite Materials Era

NEDO will take advantage of the special characteristics of thermoplastic CFRP*2 to develop structural design technology that will serve as the basis for manufacturing lighter and stronger airframes than thermoset CFRP ("the ideal airframe of the composite materials era") at production rates equivalent to or higher than those of aluminum airframes.

Development of High-rate Molding Technology for Lightweight Aircraft Fuselage Components Utilizing Thermoplastic CFRP

NEDO will design corrugated sheet sandwich structural parts using thermoplastic composite materials and develop molding/joining technology with high productivity, with the aim of applying this to next-generation lightweight floor panels.

Development of High-strength, High-speed Joint Assembly Technology between Composite Members and Other Materials in Aircraft Parts

NEDO will develop an innovative elemental technology to join thermosetting CFRP components, which have a proven track record as aircraft structural materials, by thermal welding.

Development of CMC Materials and Processes that Enable High-rate and Low-cost Production

Through the development of manufacturing technology for 1400゚C class CMC components, NEDO will achieve the CMC challenge of lower costs and higher rates by saving labor and optimizing the process for the practical application of CMC in aircraft engines.

*1 CMC: An abbreviation for Ceramic Matrix Composite, which is a ceramic matrix composite material.

*2 CFRP: An abbreviation for Carbon Fiber Reinforced Plastic, which is carbon fiber reinforced plastic.

Project Manager

MATSUI Katsunori

NEDO develops elemental technology to solve reliability and cost issues for aircraft, focusing on the development of composite materials and other related technology to meet the demand for improved fuel efficiency, environmental compatibility, maintainability, and safety of aircraft. Our goal is to establish a new low-cost, high-rate molding and assembly technology for composite components that will be essential in the manufacturing process of narrow-body aircraft, which are expected to account for 70% of future aircraft demand. For these research and development efforts, NEDO will work to secure and disseminate substantial research results for practical application as soon as possible.

Basic information

| Technical field |

|

|---|---|

| Project code | P20010 |

| Department in charge |

|

Last Updated : April 21, 2025