Research and Development Utilizing Wireless Communication Technologies to Reinforce the Dynamic Capabilities of the Manufacturing Industry

Project overview

In a situation where "uncertainty" is assumed to cause supply chain disruption risks, such as the recent global COVID-19 pandemic, it is important to strengthen "dynamic capabilities" that enable flexible and rapid responses to maintain the supply chain.

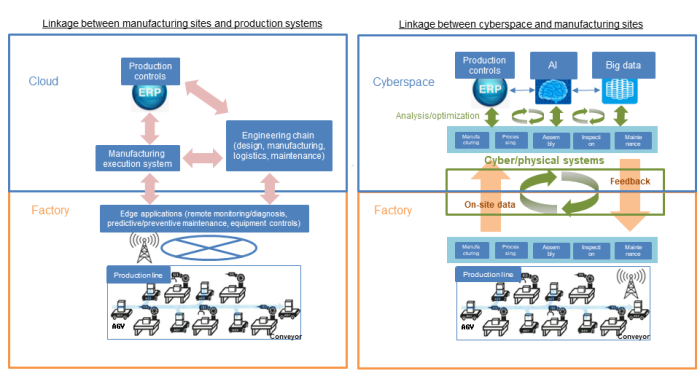

This project aims at realizing energy savings per production line and per factory as a decarbonization initiative in addition to bringing autonomous and entirely optimal operation to factories and strengthening dynamic capability at manufacturing sites by utilizing network and digital technology at those sites, such as wireless communication technology through the construction of production lines and production systems that can be flexibly and promptly rearranged and controlled, for example, by rearranging the processing order or changing production equipment according to the situation at the time and through the construction of a cyber-physical system with seamless IT/OT data collaboration.

-

Illustration of the project

Illustration of the project

Research and Development

(R&D Case Study)

Dynamic Production Lines that Can Flexibly and Promptly Rearrange and Control Existing Production Lines

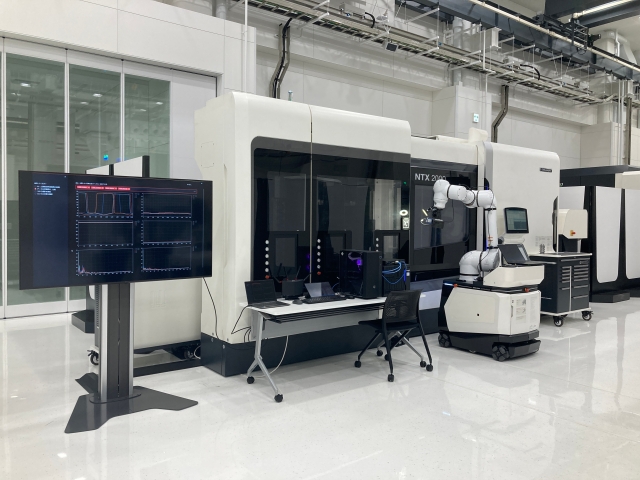

In this project, DMG Mori Co., Ltd. and FANUC Corporation have built a local 5G communication environment and established a pilot line that integrates technology to enable flexible and prompt rearrangement and control of production lines. This project aims to strengthen dynamic capability in the manufacturing industry through verification of dissemination measures for practical application, as well as rebuild simulated environments equivalent to existing manufacturing sites with diverse equipment configurations, and pursues future production lines that combine processing-assist modules adapted to the production equipment by combining cloud-based wireless cooperative control platform between automatic guided vehicle with robots (AGV) and production facilities with processing assist module adapted to existing production equipment through local 5G of a high-speed communication standard.

Automatic guided vehicle with robots (AGV) with processing assist function

(provided by DMG Mori Co., Ltd.)

Basic information

| Technical field |

|

|---|---|

| Project code | P21010 |

| Department in charge | Semiconductor and Information Infrastructure Department(TEL: +81-44-520-5211) |

Last Updated : July 9, 2024