Technology Development for the Utilization and Production of Ammonia as Fuel

Project overview

To achieve carbon neutrality by 2050, decarbonization in various fields such as electricity, transportation, heat, and industrial processes is essential.

Ammonia fuel is considered as an effective means of decarbonization in power plants and industrial furnaces because it does not emit CO2 during combustion. Moreover, by incorporating technologies like CCS into existing manufacturing processes, it is expected to reduce CO2 emissions and achieve further decarbonization by utilizing renewable energy.

This project focuses on the development of technologies utilizing combusted ammonia in industrial furnaces where CO2 emission reduction is challenging. It also involves the development of technology to reform natural gas, separate and recover CO2 during the process, and produce "Blue Ammonia" for storage.

Research and Development

R&D Item [1] "Development of Ammonia Combustion Technology in Industrial Furnaces"

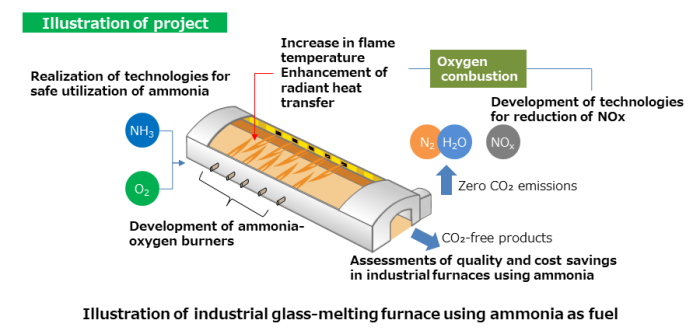

The objective is to apply the technology to industrial furnaces where heat transfer through radiation is the primary mechanism. The development of an Ammonia-Oxygen burner will be conducted, and demonstration tests will be carried out in a glass-melting furnace to verify the enhancement of radiation heat transfer and the technology for reducing NOx emissions.

Based on these results, design technology for 200 kW-class and 1 MW-class Ammonia-Oxygen burners, as well as associated technologies, will be established. The applicability to large industrial furnaces will be considered.

R&D Item [2] "Technological Development for Blue Ammonia Production"

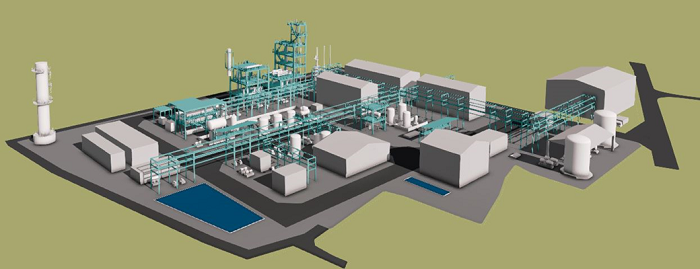

Construction of hydrogen production facilities, ammonia production facilities, and CO2 capture facilities will be undertaken. The natural gas, serving as raw material, will be reformed to produce blue hydrogen and blue ammonia. Additionally, the CO2 generated as a byproduct during the production of hydrogen and ammonia will not be released into the atmosphere. Instead, it will be separated, recovered, compressed, and stored. Through the demonstration of each element of technology in this series of processes, efforts will be made toward technological development with a view to future scaling.

-

Demonstration Test Image for Blue Ammonia Production

Demonstration Test Image for Blue Ammonia Production

Project Leaders

- R&D Item [1] PL: HAGIHARA Yoshiyuki (Senior General Manager, R&D Planning Div., R&D Unit., TAIYO NIPPON SANSO Corporation)

- R&D Item [2] PL: TAKAGI Hideyuki (Director, Research Planning Office, Department of Energy and Environment,National Institute of Advanced Industrial Science and Technology (AIST))

Basic information

| Technical field |

|

|---|---|

| Project code | P21012 |

| Department in charge |

|

Last Updated : June 2, 2025