Development of Core and Applied Technologies for the Manufacturing Processes of Next-Generation Advanced Ceramics

Project overview

Japanese fine ceramics components, including fine ceramic electronic components that support the stable operation of digital devices, account for approximately 40% of the global market. As international competition intensifies, downsizing, enhanced performance, improved reliability, and CO2 reduction processes of fine ceramic electronic components have been demanded. Therefore, it is needed to keep higher industrial competitiveness and global market share more than ever before.

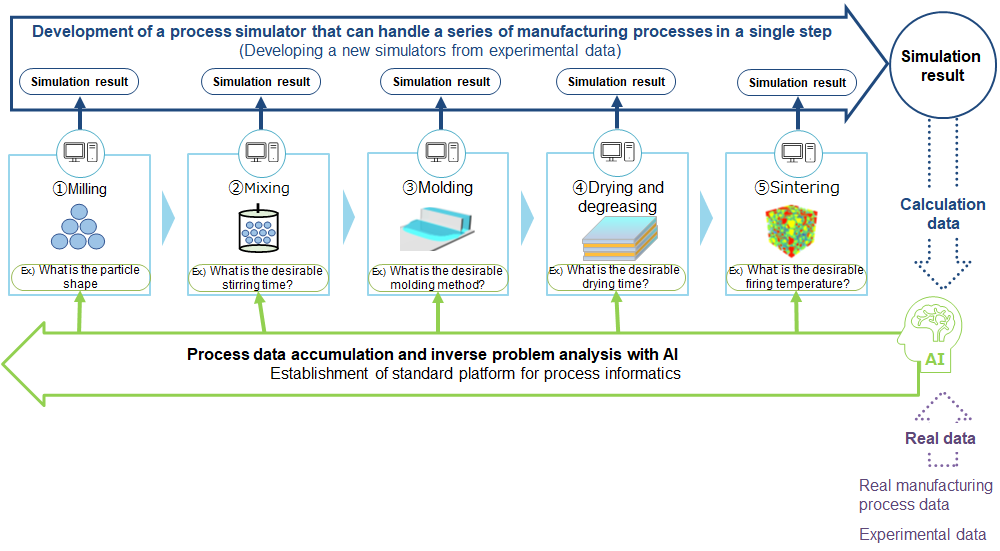

In this project, NEDO will aim to revolutionize the process development of fine ceramics manufacturing, which has traditionally based on "experience and intuition" and will develop a new process and platform in improving efficiency to shorten the process. In addition, NEDO supports the practical application of process development platforms so that it can be applied to the product development.

-

Data-driven process design

Data-driven process design

Research and Development

Development of an Innovative New Process

Core process technologies for data-driven process simulators will be developed, and feedback from real data, and more its accuracy will be improved.

- Development of visualization, analysis, and simulation technology for the manufacturing process of fine ceramics.

- Development of process Informatics (we called as PI) technology that can be analyzed by computational science for the ceramic manufacturing process from raw material powder to sintering.

- Development of innovative manufacturing process technology such as nano-order raw material production, and low temperature sintering, even if room temperature.

- Innovative process will be developed by solving inverse problem with computational science

Application Development of Innovative Process Development Platform

NEDO supports to develop PI for new manufacturing processes, which is challenging to achieve for each company.

-

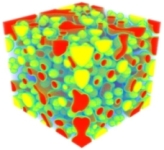

Analysis of sintering behavior of composite materials using computational science

Analysis of sintering behavior of composite materials using computational science -

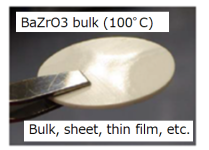

Fine ceramics sintered

Fine ceramics sintered

at low temperatures

Project Manager

In this project, NEDO will establish PI technology for fine ceramics by integrating manufacturing process technology and computational science for a series of fine ceramics processes, which is difficult to achieve for a single company. At the same time, NEDO supports companies utilization of PI technology to apply them to a wide range of product development. As the result with these efforts, NEDO aims to increase the value of shipments of fine ceramics components by approximately 1 trillion yen in 2030 (compared to 2019) and keep and strengthen the competitiveness of the Japanese fine ceramics industry.

Basic information

| Technical field |

|

|---|---|

| Project code | P22005 |

| Department in charge |

|

Last Updated : July 23, 2024