Development of Technologies for Separation and Refinement of Heavy Rare Earths

Project overview

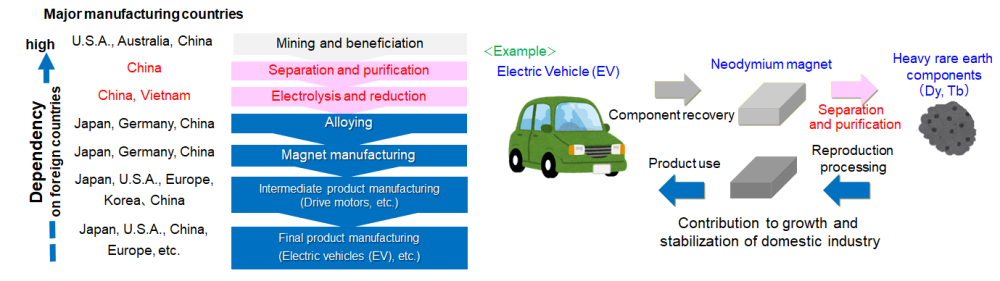

Heavy rare earth elements (hREE) such as dysprosium (Dy) and terbium (Tb) have been employed to improve the heat resistance of Neodymium (Nd) magnets in electric motors for electric vehicles (EVs) and air conditioners. The demand of hREE is expected to increase significantly as EVs become widespread. However, these hREE resources are especially rare and unevenly distributed in specific countries. Their supply risk has become a serious issue due to the instability of the geopolitical situation in recent years.

In this project, NEDO develops a cost-competitive and environment-benign technology for recovery and separation of Dy and Tb from waste, such as used Nd magnets ores production waste liquid and unconventional materials. NEDO aims to commercialize these technologies in Japan.

This project will promote hREE resource recycling and resource securing in a government-led manner in Japan. It will be helpful for stabilization materials industry in Japan, increasing independency from specific countries and reduce future supply risks of hREE.

Research and Development

Development of Technology to Recover hREE from Unconventional Resources

The goal of this subject is to develop a technology and a process for highly selective separation of hREE-including Dy and Tb from unconventional resources.

Development of High-precision Mutual Separation Technology and Refining Technology for Dy/ Tb

(1) Development of high-precision mutual separation technology

The goal of this subject is to develop a new Dy/Tb separation technology and a process compared to the conventional method (solvent extraction using a mixer-settler) which requires a large site and a high-precision mutual separation technology. The developed separation and purification process using this new technology will contribute to reducing the facility size (area saving) and to improving the processing speed and the environment load reduction.

(2) Development of a new electrolytic reduction method

The goal of this subject is to develop an energy-saving electrolytic reduction technology and a process compared to the conventional method. The new method will contribute to establishing a more cost-effective factory.

The evaluation of the manufacturing cost of the new process in this project will be conducted for commercialization in Japan.

Project Manager

It is said that the key to achieving "carbon neutrality by 2050" depends on the widespread use of electric motors. Since heavy rare earth minerals such as dysprosium and terbium are used in the neodymium magnets which are built into electric motors, the supply risk of rare earth mineral resources has recently become a situation that cannot be overlooked. NEDO expects that the developed technologies in this project will resilient the supply chain of dysprosium and terbium, and also the developed processes in this project will make a significant contribution to the future growth of Japanese industry.

Basic iniformation

| Technical field | Rare metals |

|---|---|

| Project code | P23006 |

| Department in charge |

|

Last Updated : June 20, 2025