World's First Heat and Electricity Supplied in an Urban Area Using 100% Hydrogen

- Towards Establishing Optimal Energy Control Technology in Local Communities-

April 20, 2018

New Energy and Industrial Technology Development Organization (NEDO)

Obayashi Corporation

Kawasaki Heavy Industries, Ltd.

Obayashi Corporation and Kawasaki Heavy Industries, Ltd. have achieved the world's first delivery of energy and heat in an urban area generated using a gas turbine fueled by 100% hydrogen. The verification test was conducted on April 19 and 20 as part of a NEDO project.

Tests have been carried out since the Kobe Port Island plant was completed in December 2017. Previous tests demonstrated independent generator operation using a mixture of hydrogen and natural gas, and hydrogen gas alone, as well as heat and electricity delivery using natural gas as a fuel. However, this time four neighboring facilities were simultaneously supplied with heat and electricity using only hydrogen as fuel.

Going forward, we plan to continue carrying out verification tests to collect a variety of data during each season. We also hope to establish optimal control technology for electric, heat and hydrogen energy. The goal is to build a new energy supply system that will lead to efficient energy use in local communities.

1. Overview

Hydrogen can be used in various applications such as fuel cell vehicles or generating electricity using a gas turbine. And it doesn't emit CO2 when used as an energy source. NEDO is promoting the use of hydrogen by developing technology needed to build full-scale hydrogen supply chains and energy delivery systems.

In this NEDO project, Obayashi Corporation and Kawasaki Heavy Industries, Ltd. carried out verification testing of an energy delivery system. The test, carried out on April 19 and 20, represents the world's first*1 delivery of energy and heat generated by a gas turbine fueled by 100% hydrogen to nearby facilities in an urban area. (Figure 2.)

Going forward, we plan to continue verification testing to gather data on changes in hydrogen turbine performance during each season, and the optimal heat and energy supply balance for energy control. Through these verification tests, we aim to establish an integrated energy management system (Integrated EMS*2). This will be developed with the aim of optimal control from an economic and ecological standpoint. It should enable communities to comprehensively manage heat and electricity using hydrogen and natural gas as fuel.

-

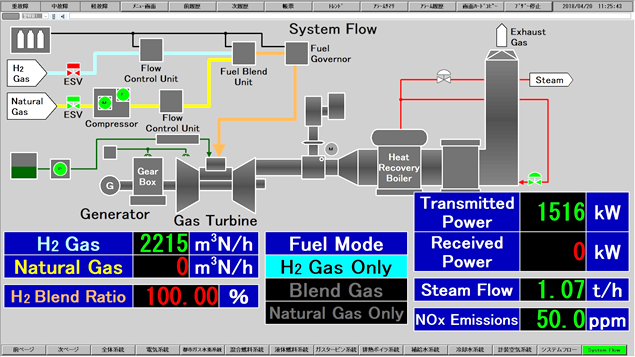

Figure 2. Control screen showing conditions when operating on 100% hydrogen

Figure 2. Control screen showing conditions when operating on 100% hydrogen

2. Details of verification testing

Last December a Hydrogen cogeneration system (CGS)*3 demonstration plant was completed on Kobe's Port Island. The plant is a 1 MW level hydrogen gas turbine power generation facility. We began test operation from January, and heat and electricity supply using natural gas from February. Since then we have tested various technologies.

The hydrogen CGS technology we developed is capable of using only hydrogen as fuel (single fuel combustion), or any mixture of hydrogen and natural gas (multi-fuel combustion). Our tests confirmed the stability of both combustion and operation.

The operational test was a basic test to verify the supply of heat (steam) and electricity generated by hydrogen CGS to 4 adjacent facilities (Kobe City Medical Center General Hospital, Kobe Port Island Sports Center, Kobe International Exhibition Hall, and Port Island Sewage Treatment Plant). This also tested its operation as an optimal energy control system within the local community (Figure 3., Figure 4.).

Then on April 19 and 20, operation was carried out using only hydrogen as fuel. We supplied 2,800 kW of heat to the Kobe City Medical Center General Hospital and Kobe Port Island Sports Center. In addition, a total of 1,100 kW of electricity was supplied to these two facilities plus the Kobe International Exhibition Hall and the Port Island Sewage Treatment Plant—four facilities in all. We were able to evaluate the performance of all systems and equipment while actually supplying energy from hydrogen alone. We also confirmed that the entire system could operate without any problems.

3. Overview of field testing

[1] Project name: Technology Development Project for Building a Hydrogen-based Society / Technology Development Project for Large-Scale Utilization of Hydrogen / Smart Community Technology Development Project Utilizing Hydrogen Cogeneration Systems

[2] Implementation Period: FY2015 – FY2018

[3] Development details

- (1) Development of hydrogen cogeneration system (hydrogen CGS)

Project lead: Kawasaki Heavy Industries

- Established technology to achieve stable combustion of hydrogen and natural gas mixtures, and of hydrogen alone

- Installed a 1 MW grade gas turbine capable of burning hydrogen and natural gas as fuel (single fuel and multi-fuel combustion). Used operations tests to collect various data on turbine speed, exhaust gas temperature, pressure, etc.

Verified stability of operation and application.

- (2) Development of an integrated energy management system (integrated EMS)

Project lead: Obayashi Corporation (project lead), Osaka University (joint researcher)

- Established an energy management system that provides combined control of electricity, heat and hydrogen and is both economical and environmentally friendly

[Notes]

- *1 World's first

- This statement is based on Kawasaki Heavy Industries' examination of public documents published by gas turbine manufacturers up to the present.

- *2 EMS

- An acronym that stands for energy management system. This is a system that uses information technology to optimize energy control and reduce energy consumption in factories and buildings.

- *3 Hydrogen Co-Generation System (Hydrogen CGS)

- CGS stands for Co-Generation System. These systems are also known as Combined Heat & Power (CHP) systems, or simply Cogeneration. They generate and supply heat and electrical power simultaneously from a single heat source.

4. Contact Information

NEDO New Energy Technology Department

Contact person: Hattori Tel: Tel: +81-44-520-5261

Obayashi Corporation Corporate Communication Department

Tel: +81-3-5769-1014

Kawasaki Heavy Industries, Ltd. Corporation Communication Department

Tel: +81-3-3435-2130