Development of a Highly Stable Magnetorheological Fluid (MR Fluid) That Does Not Sediment Even After Long Storage

―Raising Expectations for Application to Mechanical Control Field, Including Robots―

March 24, 2020

New Energy and Industrial Technology Development Organization (NEDO)

Waseda University

Nippon Paint Holdings Co., Ltd.

NEDO is carrying out Feasibility Study Program to discover promising engineering seeds. It has recently announced that it has jointly developed, with Waseda University and Nippon Paint Holdings Co., Ltd., a highly stable magnetorheological fluid (MR fluid) that does not sediment even after long storage.

An MR fluid is a type of fluid in which magnetic particles, including ferrous particles, are dispersed in a carrier fluid such as oil. MR fluid is expected for application to mechanical control field, including vehicle braking systems, vibration dampers, and robot actuators. However, there are challenges inherent with conventional MR fluid, because as magnetic particles in a carrier fluid tend to sediment, MR fluid may cause damage to equipment and destabilize its operationality after a long period of use. For this newly developed MR fluid, a polyoxyethylene fatty acid amide derivative, which has a side chain to prevent the sedimentation of magnetic particles, was used as the carrier fluid, and nanoparticles with diameters of 20 to 300 nm were added to the carrier fluid. This prevented the magnetic particles from being separated even after being left for six months, so the magnetic particles successfully presented high stress to an external magnetic field.

This achievement allows long-term use of the MR fluid, raising expectations for application to various mechanical control field, including robots.

1. Overview

A magnetorheological fluid (MR fluid)*1 is a type of fluid in which magnetic particles, including ferrous particles, are dispersed in a carrier fluid such as oil, and its viscosity changes in reaction to an external magnetic field. The use of MR fluid can simplify vehicle braking systems and vibration dampers, increase speed reduction ratios, and improve inverse mobility. Electrical control of MR fluid can adjust its viscosity agilely. These characteristics raise expectations for the application of MR fluid to medical equipment, haptics,*2 VR (virtual reality) equipment, and many other fields.

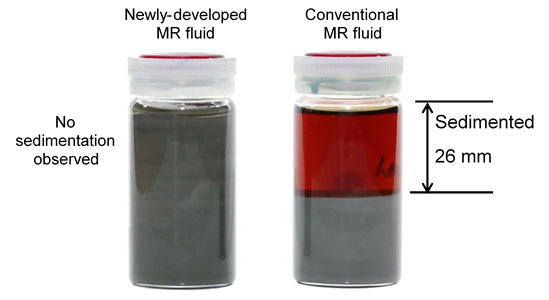

There are challenges inherent with conventional MR fluid. As magnetic particles are relatively large, with diameters of several tens of micrometers, they sediment in the carrier fluid after storage for several months, thus causing damage to equipment and destabilizing its operationality. On the other hand, MR fluids using relatively small magnetic particles (several tens to several hundreds of nanometers) have been developed to prevent sedimentation, but small magnetic particles are not practical or cost-effective for industrial use because the small size reduces output, and the use of large amounts of fine particles increases material cost.

Against this backdrop, the New Energy and Industrial Technology Development Organization (NEDO), Waseda University, and Nippon Paint Holdings Co., Ltd. jointly developed a highly stable MR fluid that does not sediment even after long storage under the NEDO Feasibility Study Program.*3 The newly developed MR fluid is mainly composed of magnetic particles with diameters of a few to 50 μm that can generate high stress. These magnetic particles are dispersed in a carrier fluid comprising a polyoxyethylene fatty acid amide derivative with a side chain to prevent the sedimentation of magnetic particles. Nanoparticles with diameters of 20 to 300 nm are added to the carrier fluid. This prevents the magnetic particles from sedimenting even after being left for six months, so they successfully present high stress to an external magnetic field.

This achievement allows long-term use of the MR fluid, raising expectations for application to various types of mechanical control devices, including robots.

2. Achievement due to This Development

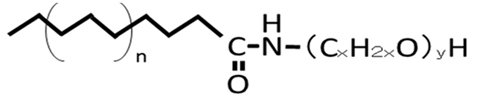

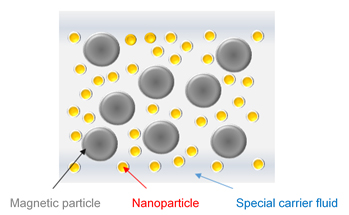

The newly developed MR fluid has the following characteristics: A polyoxyethylene fatty acid amide derivative, which has a side chain to prevent the sedimentation of large magnetic particles, is used as the carrier fluid, and a certain number of nanoparticles with diameters of 20 to 300 nm that are smaller than magnetic particles, is added to and dispersed in the carrier fluid. The polyoxyethylene fatty acid amide derivative and nanoparticles can prevent the sedimentation of large magnetic particles.

-

Figure 2: Image and Structure of Special Carrier Fluid Oriented to Magnetic Material

Figure 2: Image and Structure of Special Carrier Fluid Oriented to Magnetic Material -

Figure 3: Conceptual Diagram of Newly Developed MR Fluid

Figure 3: Conceptual Diagram of Newly Developed MR Fluid

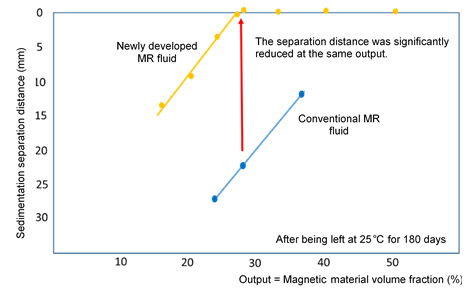

Generally, the stress that an MR fluid generates in reaction to an external magnetic field increases in proportion to the concentration of magnetic particles dispersed in the fluid. However, when the concentration of magnetic particles exceeds a certain level, the magnetic particles do not disperse but coagulate. Contrary to that, the concentration of magnetic particles needs to be lowered for a smooth and soft output, but a low concentration tends to induce sedimentation. The newly developed MR fluid can apply to a wide scope of outputs as well as maintain high stability.

-

Figure 4: Output Scope and Stability (Prevention of Sedimentation Separation)

Figure 4: Output Scope and Stability (Prevention of Sedimentation Separation)

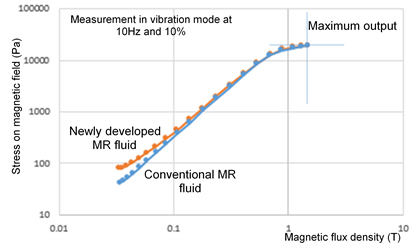

The new MR fluid can present stress to an external magnetic field (magnetic flux density) at the same level as for conventional MR fluid, and also produce a high maximum output.

-

Figure 5: Changes in Magnetic Viscoelasticity of MR Fluids (comparison between conventional MR fluid and the new fluid (30mT to 1.5T))

Figure 5: Changes in Magnetic Viscoelasticity of MR Fluids (comparison between conventional MR fluid and the new fluid (30mT to 1.5T))

3. Path Forward

NEDO, Waseda University, and Nippon Paint Holdings Co., Ltd. will continue joint development of flexible actuators for robots through use of the newly developed MR fluid.

[Note]

- *1 MR (magnetorheological) fluid

- <Principle>

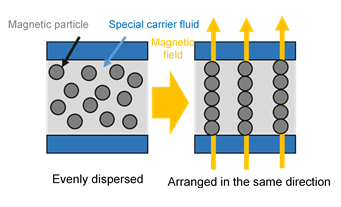

Applying an external magnetic field can control the arrangement of magnetic particles and change the viscosity of the fluid. Figure 6: Principle of MR Fluid Movement

Figure 6: Principle of MR Fluid Movement

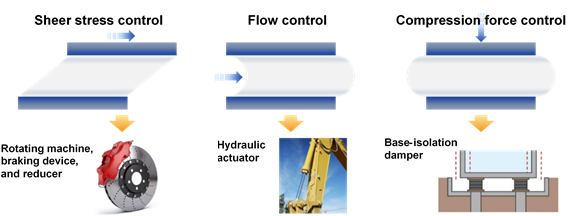

Applying an external magnetic field to control magnetic particles in the MR fluid enables various kinematic controls, including sheer stress, flow, and compression force, so its application to rotating machines, braking devices, reducers, hydraulic actuators, and base-isolation dampers, etc. is currently being studied.

-

Figure 7: MR Fluid Application Examples

Figure 7: MR Fluid Application Examples

- *2 Haptics

- Technology that provides a force, vibration, motion, etc. to a user so that the user can experience a skin sensation as feedback

- *3 NEDO Feasibility Study Program

- Program name: Innovative MR material and drive mechanism fusion research and development to achieve next-generation industrial soft robots in the new industry creation and new technology feasibility study program under the NEDO feasibility study program

- Research period: 2018 to 2020

4. Contacts

(Inquiries related to this news release)

Robot and Artificial Intelligence Technology Department, NEDO (Persons in charge: Hirano)

Tel: +81(0)44-520-5241

Research Institute for Science and Engineering, Waseda University (Person in charge: Researcher (Associate Professor): Kamezaki)

Tel: +81(0)3-3203-4387 Email: kame-mitsu@aoni.waseda.jp

Public Relations, Nippon Paint Holdings Co., Ltd. (Persons in charge: Yamamoto and Ichimura)

Tel: +81(0)6-6455-9140 Email: nphd-kouho@nipponpaint.jp