The World’s First Demonstration Test to Install a Tri-axial Superconducting Cable System into a Commercial Plant Grid Completed

-Expected to cut over 95% of transmission loss by applying it to plants with high power usage-

February 17, 2022

New Energy and Industrial Technology Development Organization (NEDO)

SWCC SHOWA CABLE SYSTEMS CO., LTD.

BASF Japan Ltd.

Translation of Japanese NEDO news release posted on December 6, 2021

The New Energy and Industrial Technology Development Organization (NEDO), SWCC Showa Cable Systems Co., Ltd. (SWCC), and BASF Japan Ltd. (BASF) have completed the world’s first demonstration test of a tri-axial superconducting cable system installed in a commercial chemical plant’s grid at BASF Japan’s Totsuka site (Totsuka Ward, Yokohama City). The test was carried out from November 2020 to September 2021 under the Strategic Innovation Program for Energy Conservation Technologies.

As a result of this test, it was verified that the system is capable of supplying power continuously and stably for about one year. It was also verified that cooling cables using liquid nitrogen is reliable and safe thereby maintaining a superconducting state even during extremely hot weather when cooling is difficult. Additionally, the test was successful in reducing the installation and operating costs of the system by using existing facilities.

By adopting the system in a plant that uses more than 30 MW of large-scale power compared to conventional systems, there is a possibility of losses during power transmission being reduced by more than 95% and the effect of reducing CO2 emissions has also been confirmed.

These results prove that the system can contribute to a decarbonized society as an efficient power transmission system.

Figure 1. Cabling layout at installation site

1.Overview

The effective use of electric power has become an urgent issue, with the need to reduce greenhouse gas emissions as a countermeasure to global warming. As a highly efficient power supply technology that does not cause power loss due to its zero electrical resistance, superconductivity technology has attracted a lot of attention from various fields such as electric energy, electronics, medicine, and transportation. However, in order to maintain a superconducting state, the technology must be kept cool with liquid nitrogen, and the like. Therefore, it was necessary to establish a low-cost operational technology for practical use.

Against this backdrop, NEDO has been promoting the Strategic Innovation Program for Energy Conservation Technologies*1 with the aim of building an energy-saving economy and society and strengthening industrial competitiveness in Japan. In this program, Showa Cable Systems Co., Ltd. (SWCC) and BASF Japan Ltd. (BASF) completed a demonstration test in September 2021 at BASF Japan’s Totsuka site, which they had been jointly carrying out since November 2020*2.

A low cost and compact tri-axial superconducting cable system developed from FY2017 to FY2018 was installed*3 for the test. As a result, it was verified that the system is capable of supplying power continuously and stably for about one year. It was also verified that cooling cables using liquid nitrogen is reliable and safe thereby maintaining a superconducting state even during extremely hot weather when cooling is difficult. Additionally, the test was successful in reducing the installation and operating costs of the system by using existing facilities.

The energy-saving effect of installing the system will be even greater when applying it to a grid that energizes a large current. Therefore, it is expected that it will be applied to factories that use large amounts of electricity, bus bars in power plants, and in the future, to the infrastructure of smart cities. In plants that handle cold heat, such as liquid nitrogen, the cold heat can be used for cooling, eliminating the need to install a chiller, making the system relatively low-cost to operate and highly effective to install. By replacing a conventional cable with the system in plants that use more than 30 MW of large-scale power, there is a possibility that losses during power transmission can be reduced by more than 95%. The effect of reducing CO2 emissions has also been confirmed, therefore proving that this cable system can contribute to a decarbonized society as an efficient power transmission system.

2.Results of this project

(1) Development of a low-cost, compact cable system

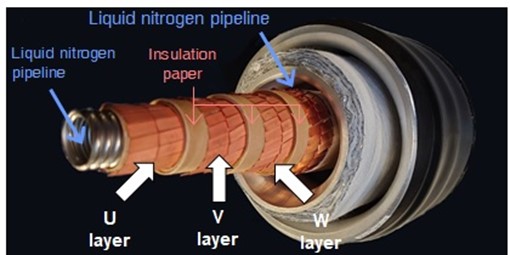

In practical application development (FY2017–FY2018), a low-cost, compact, tri-axial superconducting cable for general plants was developed, as shown in Figure 2. The concentric arrangement of the three conducting phases results in a net cancellation of the magnetic fields during normal operation. As a result, the amount of coated conductor used can be reduced to one-third of that of single-core cables, and the total cost of coated conductor can be reduced to two-thirds. In addition, by using a tri-axial type, a single cable is used to achieve a compact and flexible structure.

-

Figure 2. Tri-axial superconducting cable

Figure 2. Tri-axial superconducting cable

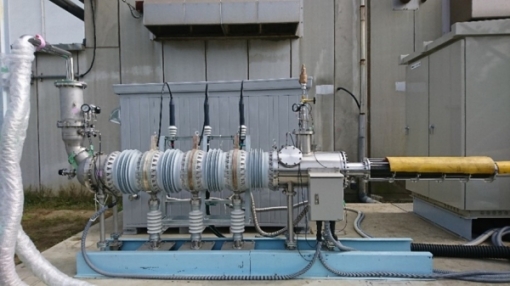

Conventional single-core cables require six terminals to supply power to each of the three-phase ACs independently. On the other hand, the tri-axial superconducting cable has only two terminals by arranging the electrodes coaxially, resulting in a compact shape as shown in Figure 3.

-

Figure 3. Terminal of tri-axial superconducting cable

Figure 3. Terminal of tri-axial superconducting cable

In conjunction with the tri-axial structure of the cable, the interconnection also adopted a coaxial cable joint structure that was developed from existing technology. As a result, a compact shape with an outer diameter of 340 mm was achieved, as shown in Figure 4. A cable joint technology with low electrical resistance was established, making it possible to extend the cable.

-

Figure 4. Cable joint of tri-axial superconducting cable

Figure 4. Cable joint of tri-axial superconducting cable

A subcooled cooling system that was jointly developed by Air Water Inc. and SWCC, as shown in Figure 5, was adopted in this test. In this cooling system, liquid nitrogen stored in a sealed container is depressurized to cool it to minus 200℃ using the latent heat of evaporation when the liquid changes to gas. The concept of the design is to use liquid nitrogen, which the plant has in large quantities, as a refrigerant, and recover nitrogen gas exhausted to reduce pressure for reuse in the plant.

Since the tri-axial superconducting cable system is used with constant cooling, it is necessary to constantly monitor the status of liquid nitrogen used for cooling. In this test, sensors to measure pressure, temperature, flow rate, and liquid level were arranged at both terminals, and this data was managed by a monitoring system. A function to switch the power transmission circuit in case of emergency has also been added.

-

Figure 5. Subcooled cooling system

Figure 5. Subcooled cooling system

(2) Confirmed the ease of cable installation and energy-saving effects by carrying out this test at an actual plant.

A special condition of this test was that it was necessary to use the plant’s existing facilities, so the cable was installed on an existing rack, which is located about 5 meters above the ground. Therefore, it was necessary that the cable was bent 90 degrees (bending radius 1.5 meters) at four locations as shown in Figure 7, but the flexibility of the cable allowed it to be installed without any problems. Although the flow path of liquid nitrogen becomes narrower at bends with a compact cable, it can flow over long distances (approximately 400 meters round trip) in the system without any problems, confirming that it can be used for complex plant layouts.

-

Figure 6. Tri-axial superconducting cable installation in an existing rack

Figure 6. Tri-axial superconducting cable installation in an existing rack

(5 meters high) -

Figure 7. Bending parts of tri-axial superconducting cable

Figure 7. Bending parts of tri-axial superconducting cable

(90 degrees, bending radius 1.5 meters)

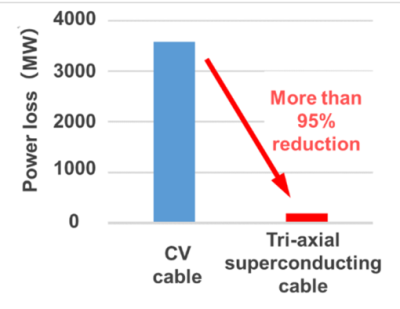

Reduced heat penetration due to the compactness of parts such as cables, terminals and intermediate connections, and the energy-saving effect of utilizing the existing liquid nitrogen storage in the plant were almost exactly as designed. Based on the results of this test, a comparison was made between the power transmission loss generated over a period of one year by energizing a 1,000 m-long tri-axial superconducting cable and a conventional cable (CV cable) with 3,000 A of a three-phase AC (Figure 8). This comparison shows that replacement with this tri-axial superconducting cable system is expected to reduce the amount of power loss generated with the conventional cable by 95%.

-

Figure 8. Comparison of annual power transmission loss

Figure 8. Comparison of annual power transmission loss

In this test, power was supplied without incident for about one year, and the stable circulation of liquid nitrogen was confirmed despite extremely hot weather. Conventional liquid nitrogen pumps require overhauling every few months, but a liquid nitrogen pump developed in this project has achieved accident-free and maintenance-free operation for about one year. This means that the maintenance of the liquid nitrogen pump can be carried out in conjunction with regular plant inspections, proving its high practicality.

In addition, as a result of constant monitoring throughout the test period by a monitoring system developed for this test, the effectiveness of the tri-axial superconducting cable system was confirmed, and it was also confirmed that the monitoring system can be unmanned.

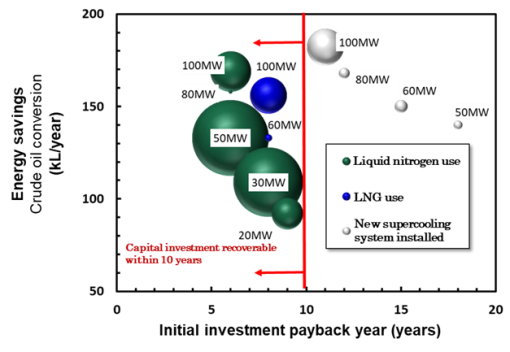

By applying the system to plants, significant energy-saving effects can be expected. Figure 9 shows the relationship between the initial investment payback period and energy savings when the system is installed. Each bubble is color-coded to indicate the presence and type of cooling system being used, and the size to indicate the number of alternative lines. For example, if the initial investment payback period is set at 10 years or less, 1,080 lines (about 300 sites) will be targeted. Among those lines, there are 420 lines (about 190 sites) that use liquid nitrogen (green bubbles) and 30 MW of electricity. The annual energy saving would be about 110 kl in crude oil equivalent, indicating that the initial investment can be recovered in about 8 years.

-

Figure 9. Relationship between the initial investment payback period and energy savings

Figure 9. Relationship between the initial investment payback period and energy savings

A video of the demonstration test is available on the NEDO Channel, NEDO's official YouTube channel, from 1:00 p.m. JST on Monday, December 6, 2021.

The world first trial, completed a demonstration test to install the superconducting cable.

The world first trial, completed a demonstration test to install the superconducting cable.

The world first trial, completed a demonstration test to install the superconducting cable.

3. Future plans

Through this demonstration test, NEDO, SWCC, and BASF verified the installation method and operational management method at a private plant, as well as the energy-saving effects, and obtained results as expected. Work will continue towards the practical application of the system and link the results to the reduction of greenhouse gas emissions through the effective use of electric energy to achieve a decarbonized society.

[Notes]

- *1 Strategic Innovation Program for Energy Conservation Technologies

Research and development items: Development and Demonstration/Development of a Low-Cost Triaxial

Superconducting Power Cable for In-Plant Use

Period: 2017 - the end of October 2021

Project participant: SWCC Showa Cable Systems Co., Ltd.

Project participant's contractors: BASF Japan Ltd., Air Water Inc., Kyushu University, Tohoku University

- *2 Reference: NEDO news release, June 12, 2019, “World's first demonstration test of tri-axial superconducting cable to be started at a private plant”

世界初、民間プラントでの三相同軸超電導ケーブルの実証試験開始へ

世界初、民間プラントでの三相同軸超電導ケーブルの実証試験開始へ

- *3 Reference: NEDO news release, November 11, 2020, "World's first installation of tri-axial superconducting cables in a private plant.”

世界初、民間プラントに三相同軸超電導ケーブルを敷設

世界初、民間プラントに三相同軸超電導ケーブルを敷設

4.For more information, please contact:

(Inquiries related to this news release)

NEDO Energy Conservation Technology Department, Development Group I

Contact persons: Kinoshita, Iwamoto TEL:+81-44-520-5281

Strategy Section Business Strategy Planning Dept.

SWCC SHOWA HOLDINGS CO., LTD.

TEL:+81-44-223-0520

Communications

BASF Japan Ltd.

TEL: +81-3-5290-2510

Email: communications-jp@basf.com

(For inquiries related to superconducting cable system technologies and products)

Superconducting Applied Products and Development Section

Research & Development Center

SWCC SHOWA CABLE SYSTEMS CO., LTD.

TEL: +81-42-773-7163