In a world first, a bearing manufacturer starts operating its own plain bearing bench testing machine for wind turbines, contributing to reliability and cost-reduction in offshore wind power

June 5, 2025

New Energy and Industrial Technology Development Organization (NEDO)

Daido Metal Co., Ltd. became the first bearing manufacturer in the world to install its own plain bearing bench testing machine for wind turbines at the newly established Wind Power Technology Research Center located at Daido Metal Saga Co., Ltd., a consolidated subsidiary. The Development of Plain Bearings for Wind Turbine Main Shafts is part of NEDO’s Green Innovation Fund Project, Cost Reductions for Offshore Wind Power Generation.

The bench testing machine makes it possible to simulate the operating environment of the main shaft plain bearings in offshore wind power generation, allowing for improved evaluation and more accurate technical proposals to wind power generation equipment manufacturers. This technological development is expected to improve the reliability of offshore wind power generation, a growing industry, and contribute to reducing the LCOE (levelized cost of electricity.)

Figure 1. Unveiling of the bench testing machine

1.Background

To achieve carbon neutrality by 2050, Japan needs to make maximum use of renewable energy. Offshore wind power generation can be implemented on a large scale at low cost, and the expected economic ripple effects make it a promising part of any renewable energy mix. Steady progress is being made, but even with increasingly popular fixed-bottom offshore wind turbines, there is growing demand for further reductions in power generation costs due to issues such as recent rises in the cost of materials.

Japan has many companies with promising core technologies, but these are not being fully utilized due to the lack of domestic wind turbine manufacturers. It is essential to build a resilient domestic supply chain while promoting international collaboration to develop cutting-edge technologies in order to create next-generation industries that can compete internationally.

It is against this background that NEDO’s Green Innovation Fund Project, Cost Reductions for Offshore Wind Power Generation, has been ongoing since fiscal year 2021. Daido Metal is developing technology under this project*1 to verify the effectiveness of using plain sliding bearings as the main bearings in wind turbine generators.

2.Results

(1)Development of plain bearings

By replacing conventional rolling bearings with split pad plain bearings in the main shafts of offshore wind turbines, Daido Metal hopes to ease the burden and cost of maintenance and replacement while improving equipment utilization rates and reducing the LCOE.

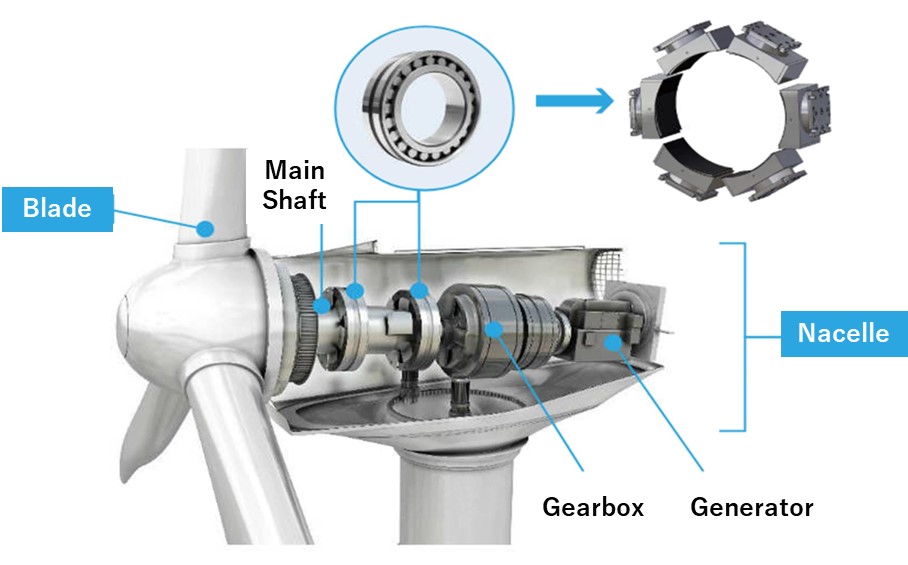

Figure 2. Overview of a wind turbine nacelle*2

(2)Use of bench test machines for plain bearings

The new Wind Power Technology Research Center established at affiliate Daido Metal Saga will evaluate the plain bearings proposed by the company. In order to achieve this, Daido Metal installed its own dedicated plain bearing bench testing machine for wind turbines with a shaft diameter of 1,000 millimeters, the world’s first by a manufacturer independently. Installation was completed at the end of April 2025, and operation began shortly after.

The machine can simulate an operating environment, including circumferential speed and specific load, equivalent to what plain bearings for offshore wind turbine main shafts would be subjected to. By making it possible to carry out evaluation experiments before plain bearings are adopted in a real environment, independent proposals for bearings and peripheral systems can be generated. This will reduce the labor and cost needed for testing borne by wind turbine manufacturers and simplify the adoption process.

Figure 3. The newly established Wind Power Technology Research Center at Daido Metal Saga Co., Ltd.

3.Future plans

Daido Metal will utilize the data obtained from the plain bearing bench testing machine to promote the real-world social implementation of plain bearings in offshore wind turbines as it works to reduce power generation costs.

NEDO will continue to strengthen the technical proposal capabilities of these promising domestic parts manufacturers, build a supply chain based on international collaboration, and contribute to reducing the LCOE of offshore wind power generation.

[Notes]

- *1 Project name: Green Innovation Fund Project, Cost Reductions for Offshore Wind Power Generation, Technology Development Project for Next-Generation Wind Turbines, Development of Plain Bearings for Wind Turbine Main Shafts

- Project period: 2022 to 2026

- Project overview: Cost Reductions for Offshore Wind Power Generation

- *2 A wind turbine nacelle consists of the gearbox, generator, brakes, rotor shaft and main shaft. It is installed at the top of the wind turbine tower and connected to the blades by the rotor shaft and hub.

4.For more information, please contact:

- NEDO, Renewable Energy Department, Wind & Marine Unit,

- Email: windgroup[*]ml.nedo.go.jp

- * To send an inquiry by email, please replace [*] with @ in the above email address