Development of Continuous Production and Process Technologies of Fine Chemicals

Project overview

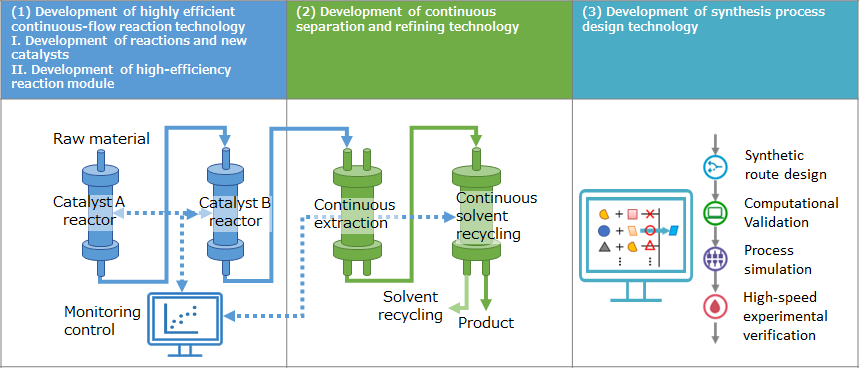

This project uses catalyst technology to replace the energy-intensive and waste-producing batch process in the growing field of functional chemicals with an energy-saving and efficient connected flow process. In addition, NEDO will develop synthesis process design technology using process information, reaction data, etc. NEDO will promote this research and development through industry-academia collaboration and create production process innovations that are different from conventional ones.

-

Continuous precision production process

Continuous precision production process

Research and Development

Based on the research and development described below, catalyst technology will be advanced, and various modules will be improved in the future. A multi-stage system capable of flow production and synthesis process design technology will be established. Additionally, a single-step system using targeted compounds will be validated.

Development of High-efficiency Reaction Technology

Catalysts and reactions for connected flow are being developed.

- More than 20 types of highly efficient flow reactions using excellent solid catalysts have been developed, and the practical application of some of them has been considered.

- Three types of reactors (one-phase system, two-phase system, and reaction separation) have been developed, and preparations are being made for the commercialization of the one-phase system reactor.

- The principle of a highly sensitive online ICP analysis method has been established.

Development of Continuous Separation and Purification Technology

This technology separates the target substance produced by a reaction.

- Basic technology for separation and purification, such as extraction separation, membrane separation, and compact horizontal distillation columns, was developed.

- Prototype modules and the coupling of multiple modules were discussed.

Development of Synthesis Process Design Technology

PI (Process Informatics) significantly reduces design time.

- Development of synthesis process design technology has begun.

- Improvement of the computational environment, expansion of the database, selection of target compounds, and demonstration of device design simulations were conducted.

Development Example

The one-phase reaction module (8g/h) achieved the same reaction results as the small reactor (0.2g/h), and the temperature inside the reactor was successfully equalized.

One-phase system reactor

Reference Links (Available only in Japanese)

- FY2022 Development of continuous precision production process technology for functional chemicals - Interim results report meeting

Development of continuous precision production process technology for functional chemicals (flow synthesis PJ) Interim results report meeting - Program/Presentation Materials (41.0MB)

Development of continuous precision production process technology for functional chemicals (flow synthesis PJ) Interim results report meeting - Program/Presentation Materials (41.0MB)

- FY2021 Interim evaluation report

Development of continuous precision production process technology for functional chemicals (16.6MB)

Development of continuous precision production process technology for functional chemicals (16.6MB)

- FY2018 Technology Strategy Center Report TSC Foresight Vol.31

Toward the Formulation of Technology Strategies in the Field of Functional Chemicals Manufacturing Processes (1.3MB)

Toward the Formulation of Technology Strategies in the Field of Functional Chemicals Manufacturing Processes (1.3MB)

Project Manager

Promotion of CO2 Reduction, Energy Conservation, and Strengthening Industrial Competitiveness

NEDO promotes significant energy savings and CO2 and waste reduction through the consolidated flow method. Furthermore, NEDO uses PI (Process Informatics) to create process innovations and strengthen the industrial competitiveness of functional chemicals.

Basic information

| Technical field |

|

|---|---|

| Project code | P19004 |

| Department in charge |

|

Last Updated : July 24, 2024