Sustainable Aviation Fuel Produced from Waste Wood and Microalgae Supplied to Regular Flights

-Contributing to Carbon Neutrality by 2050 With the Goal of Social Implementation of SAF-

June 18, 2021

New Energy and Industrial Technology Development Organization (NEDO)

The New Energy and Industrial Technology Development Organization (NEDO) has entrusted the Development of Production Technologies for Biojet Fuels project to Mitsubishi Power, Ltd., JERA Co., Inc., Toyo Engineering Corporation, and the Japan Aerospace Exploration Agency (JAXA), who are working to develop production technology for fuel using waste wood as raw material, and IHI Corporation, who is working to develop production technology for fuel made from microalgae. The Biojet Fuel produced by each technology was supplied to regular flights on June 17 as sustainable aviation fuel (SAF).

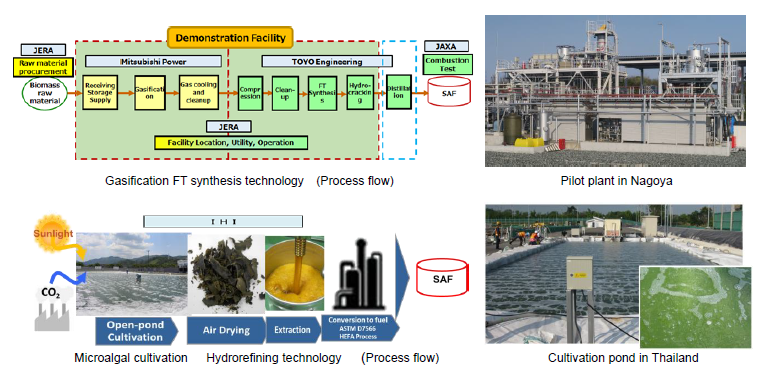

This fuel was produced by gasification FT synthesis technology, which synthesizes liquid fuels after gasifying solid wood cellulose, and hydrorefining technology, which refines oil derived from microalgae. Both technologies have been confirmed to be compliant with ASTM D7566, the international standard for SAF.

NEDO will continue to carry out research and development projects for SAF production to establish large-scale reliable technology and efficient production processes to reduce production costs. This will pave the way for carbon neutrality by 2050 and contribute to reducing greenhouse gas emissions in the aviation field.

1. Overview

The International Civil Aviation Organization (ICAO) and the International Air Transport Association (IATA) share a common theme of mitigating global warming through the reduction of greenhouse gas emissions. In particular, both bodies believe that the introduction of sustainable aviation fuel (SAF)*1 is an effective measure to reduce greenhouse gas emissions.

With a view to commercializing SAF, the New Energy and Industrial Technology Development Organization (NEDO) has been promoting the Development of Production Technologies for Biojet Fuels*2 project since FY2017, aiming to demonstrate an integrated production system from the procurement of waste wood and cultivation of microalgae as raw materials to the production of pure biojet fuel*3, as well as to realize supply chains which include refueling to aircraft.

As part of this effort, a demonstration test for SAF integrated production using waste wood as feedstock was carried out at a pilot plant built in the facilities of JERA Co., Inc. (in Nagoya, Aichi prefecture) by utilizing the gasification FT synthesis technology*4 that synthesizes liquid hydrocarbon fuel after gasifying solid wood cellulose. In this test, JERA Co., Inc. procured the raw material and operated the pilot plant, Mitsubishi Power, Ltd. gasified the raw material, and Toyo Engineering Corporation synthesized liquid hydrocarbon fuel from the generated gas (FT synthesis) and distillated it and then constructed a supply chain after mixing*5 the SAF, while the Japan Aerospace Exploration Agency (JAXA) implemented performance characteristic tests on combustion of the produced SAF. In March 2021, the SAF, in which pure biojet fuel produced from waste wood is mixed with existing fossil fuel (JET A-1), was confirmed to comply with the international standard of ASTM D7566 Annex1*6.

For the production method utilizing hydrorefining technology to refine oil derived from microalgae*7, IHI Corporation established integrated production technology from large-scale cultivation to SAF production and constructed a supply chain by using its existing facility in Kagoshima city, Kagoshima prefecture, and a new pilot outdoor cultivating facility in Saraburi province, Thailand. The SAF, in which pure biojet fuel made from microalgae is mixed with existing fossil fuel (JET A-1), was confirmed to comply with the international standard of ASTM D7566 Annex7*8 in April 2021.

Based on these results of NEDO’s project, the SAF produced with both technologies has now been supplied to regular flights departing from Tokyo International Airport (Haneda Airport in Ota-ku, Tokyo).

2. Overview of SAF-Supplied Regular Flight Routes*9

1. SAF made from waste wood

- Date: June 17, 2021

- Flight number: Japan Airlines Fight 515

- Section: Tokyo International Airport to New Chitose Airport

- Aircraft: Airbus A350-900

2. SAF made from microalgae

- (1) Date: June 17, 2021

- Flight number: Japan Airlines Flight 515

- Section: Tokyo International Airport to New Chitose Airport

- Aircraft: Airbus A350-900

- (2) Date: June 17, 2021

- Flight number: All Nippon Airways Flight 031

- Section: Tokyo International Airport to Osaka International Airport (Itami Airport)

- Aircraft: Boeing 787-8

3. Future plans

NEDO will address SAF production research and development to establish large-scale reliable production technology and an efficient production process to reduce production costs toward the upcoming full-scale dissemination of SAF. By doing so, NEDO aims to further reduce greenhouse gas emissions in the aviation field and realize Carbon Neutrality by 2050. Please refer to the following URL for details:

NEDO Channel (YouTube)  "NEDO Development of Production Technologies for BIOJET FUELS" (English and Japanese)

"NEDO Development of Production Technologies for BIOJET FUELS" (English and Japanese)

[Notes]

- *1 SAF

- Abbreviation for sustainable aviation fuel.

- *2 Development of Production Technologies for Biojet Fuels

- Project overview:

Development of Production Technologies for Biojet Fuels

Development of Production Technologies for Biojet Fuels

Project period: FY2017 to FY2024 - *3 Pure biojet fuel

- 100% pure biojet fuel produced from biomass feedstock. Also called neat fuel.

- *4 Gasification FT synthesis technology

- The technology in which solid materials such as wood cellulose are reacted with water vapor and a small amount of oxygen in a gasification furnace to produce carbon monoxide and hydrogen (gasification), which are then synthesized into liquid hydrocarbons (fuel) in FT reactor using a catalyst. (Fischer-Tropsch Process).

- *5 Mixing

- When SAF is used in aircraft, it must be compliant with the respective Annex standards set by ASTM International, an international standard-setting body consisting of industrial materials standards and test method standards, and be blended with existing fossil fuel (JET A or JET A-1). For Pure biojet fuel blend of SAF, regulations limits are set at 50% for Annex1 and 10% for Annex7.

- *6 ASTM D7566 Annex1

- The standard for the Fischer-Tropsch (FT) conversion process in ASTM standard D7566.

- *7 Hydrorefining technology to refine oil derived from microalgae

- The technology for synthesizing liquid hydrocarbons (fuel) by hydrotreating crude oil (mainly composed of hydrocarbons) made from the microalgal Botryococcus braunii.

- *8 ASTM D7566 Annex7

- The standard for the conversion process HC-HEFA SPK (Synthetic Paraffinic Kerosene from Hydroprocessed Hydrocarbon, Esters and Fatty Acids) in ASTM D7566. IHI Corporation applied for this standard to ASTM on its own, and it was approved in May 2020.

- *9 Overview of SAF-supplied regular flight routes

- The breakdown of the refueling volume is as follows:

Japan Airlines Fight 515, June 17, 2021

Total refueling fuel amount is approximately 8,700l

Wood waste feedstock SAF 2,195l(25%), and Microalgae feedstock SAF 938l (11%)

All Nippon Airways Flight 031, June 17, 2021

Total refueling fuel amount is approximately 5,000l

Microalgae feedstock SAF 988l (20%)

4. For more information, please contact:

(Inquiries related to this news release)

NEDO New Energy Technology Department

Contact Persons: Furukawa, Shibahara, Kobayashi, Iwasa

TEL: 044-520-5271 E-mail: nedo.biofuel@ml.nedo.go.jp