Strategic Innovation Program for Energy Conservation Technologies

Project overview

In this project, NEDO aims to achieve sustainable energy conservation compatible with economic growth. Focusing on key technologies in the industrial, residential (household and business), transportation, and other sectors as outlined in the "Energy Conservation Technology Strategy, (Available only in Japanese) " NEDO provides seamless support for the development of technologies that are expected to have a significant energy-saving effect by 2030, leading to their commercialization.

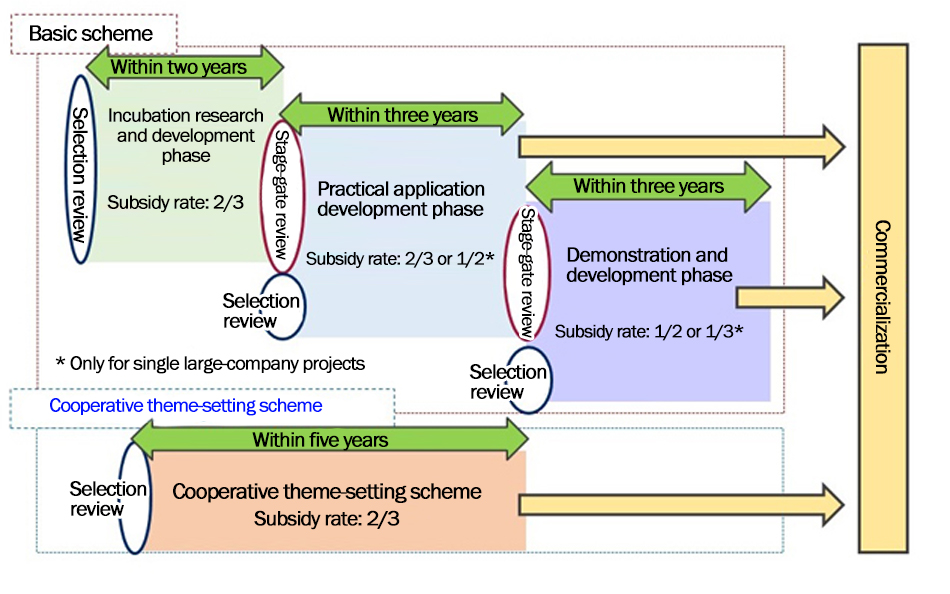

■ Scheme overview

-

Scheme Overview Diagram

Scheme Overview Diagram

Research and Development

| Phase for Research and Development |

Basic scheme | Theme-based Scheme for Business Collaboration |

||

|---|---|---|---|---|

| Incubating Research and Development | Developing Practical Application | Developing Verification | ||

| Project period | Within two years | Within three years | Within three years | Within five years |

| Maximum Cost on Technological Development (*) (subsidy rate) |

20 million yen per project per year (NEDO burden ratio: 2/3) |

300 million yen per project per year (2/3 or 1/2) |

1 billion yen per project (1/2 or 1/3) |

1 billion yen per project (2/3) |

| Overview | Conduct preliminary research for developing practical application and verification to establish specific methods for addressing challenges, clarify the prospects for commercialization, and formulate development and implementation scenarios. | Technology development that utilizes existing technologies, know-how, and other relevant assets owned by companies, universities, and similar entities as a basis to achieve applications and adaptations contributing to energy conservation. Projects under this category generally aim for commercialization within 3 years after the completion of the development. | Technical development focused on overcoming obstacles hindering commercialization and acquiring verification data that facilitates more reliable commercialization. Projects under this category generally aim for prompt commercialization after the completion of development. | Development of unified evaluation methods for innovative technologies development and new technologies aimed at addressing common challenges within an industry and challenges spanning different industries. This involves collaboration and cooperation among multiple entities to set themes (technologies development challenges) that should be addressed collectively. The goal is to achieve energy savings through the practical implementation and widespread adoption of the developed technologies. Projects under this category generally aim for commercialization within three years after completion of development. |

* The maximum cost on technological development is the total annual project cost (the NEDO subsidy amount + the amount paid by the implementer).

Adoption results

In this project, NEDO supports the development of a wide range of energy-saving technologies. In the industrial sector, this includes technologies for energy-efficient manufacturing processes, energy-saving systems, processing technologies, and acceleration technologies for energy-efficient products. The residential and commercial sectors focus on Zero Energy Buildings (ZEB) and Zero Energy Houses (ZEH), energy-efficient information equipment and systems, and comfortable and energy-efficient human factors. In the transportation sector, the emphasis is on next-generation vehicles, Intelligent Transport Systems (ITS), and Smart Logistics Systems. In the energy conversion and supply sector, NEDO focuses on high-efficiency thermal power generation, next-generation power distribution technologies, Cogeneration, and heat utilization systems. As cross-sectoral technologies, NEDO supports innovative energy management technologies, power electronics, next-generation heat pump systems, and more.

- (Available only in Japanese)

- FY2020First Posting

List of Adopted Projects (36KB) |

List of Adopted Projects (36KB) |  Adoption Theme Overview (2.1MB)

Adoption Theme Overview (2.1MB) - Additional Emergency Posting

List of Adopted Projects (48KB) |

List of Adopted Projects (48KB) |  Adoption Theme Overview (2.4MB)

Adoption Theme Overview (2.4MB) - FY2019First Posting

List of Adopted Projects (41KB) |

List of Adopted Projects (41KB) |  Adoption Theme Overview (2.0MB)

Adoption Theme Overview (2.0MB) - Second Posting

List of Adopted Projects (60KB) |

List of Adopted Projects (60KB) |  Adoption Theme Overview (4.0MB)

Adoption Theme Overview (4.0MB) - FY2018

List of Adopted Projects(155KB) |

List of Adopted Projects(155KB) |  Adoption Theme Overview (1)(2.9MB) |

Adoption Theme Overview (1)(2.9MB) |  Adoption Theme Overview (2) (765KB)

Adoption Theme Overview (2) (765KB) - FY2017

List of Adopted Projects (Basic Scheme) (62KB) |

List of Adopted Projects (Basic Scheme) (62KB) |  Adoption Theme Overview (Basic Scheme)(4.9MB)

Adoption Theme Overview (Basic Scheme)(4.9MB)  List of Adopted Projects (Theme Setting) (58KB) |

List of Adopted Projects (Theme Setting) (58KB) |  Adoption Theme Overview (Theme Setting) (872KB)

Adoption Theme Overview (Theme Setting) (872KB)- FY2016

List of Adopted Projects (94KB) |

List of Adopted Projects (94KB) |  Adoption Theme Overview (1.6MB)

Adoption Theme Overview (1.6MB) - FY2015First Posting

List of Adopted Projects (120KB) |

List of Adopted Projects (120KB) |  Adoption Theme Overview (1) (3.4MB) |

Adoption Theme Overview (1) (3.4MB) |  Adoption Theme Overview (2) (1.4MB)

Adoption Theme Overview (2) (1.4MB) - Second Posting

List of Adopted Projects (58KB) |

List of Adopted Projects (58KB) |  Adoption Theme Overview (1.3MB)

Adoption Theme Overview (1.3MB)

Results Examples

(1) News Release

News releases before FY2021 can be found here

(Available only in Japanese)

(2) NEDO Channel (Theme introduction through videos)

Available only in Japanese

The world's first trial, completed a demonstration test to install the superconducting cable

The world's first trial, completed a demonstration test to install the superconducting cable- Development of Low Power Consumption Graphics Processor

- CO2Development of Energy-Saving Refrigerated and Frozen Showcase Equipment and Systems Utilizing CO2 Refrigerant

Low-Temperature Waste Heat Utilization

Low-Temperature Waste Heat Utilization CFRP Recycling Technology

CFRP Recycling Technology- Cloud-Based Energy Management Technology

Basic information

| Technical field | Energy conservation Cross-sectoral proposal-based activities |

|---|---|

| Project code | P12004 |

| Department in charge | Frontier Department (TEL: +81-44-520-5245) |

Last Updated : April 21, 2025